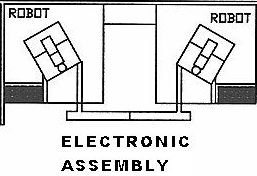

Electronic Assembly

This is the area of the factory where the electronic components are soldered onto the Printed Circuit Board (PCB), this is done by 2 robotic machines in this department that place and solder all the components on the PCBs. The components are installed by a pick a place process that also uses an adhesive to temporarily attach the components to the PCB, after this the PCB go through continous flow solder process in which a river of molten solder touches the bottom of the PCB and permanently attaches the components.