Scroll Wheel Assembly (Critical Points):

Part # |

Component |

Material Used |

Mfg. Process |

Qty. |

Production Rate |

Manufacturing Cost $ / Piece |

13 |

Wheel |

Grey Rubber |

Injection Molding to Shaft |

1 |

16 at a time |

$ 0.090 |

14 |

Shaft |

Black Plastic |

Injection Molding |

1 |

16 at a time |

$ 0.070 |

Total Cost: |

$ 0.160 |

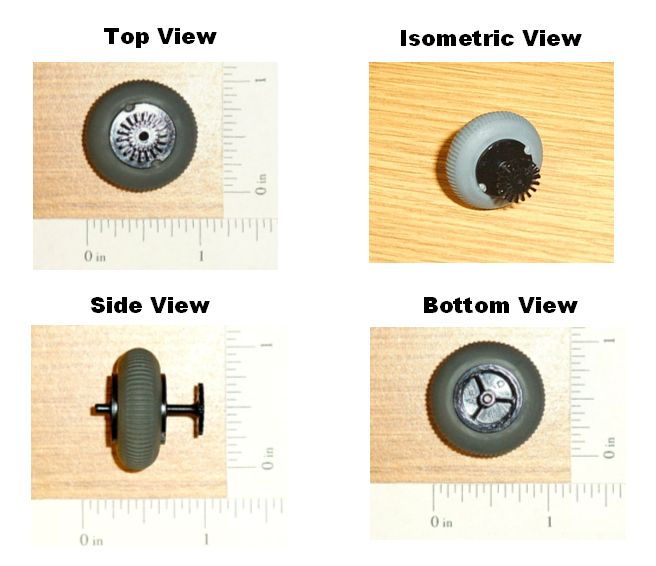

The Scroll Wheel Assembly is made up from 2 other components; the Scroll Shaft and the Scroll Wheel. The Scroll Shaft is manufactured first then the Scroll Wheel is molded around the Scroll shaft in another process thus the Scroll Wheel is never a separate component as it is permanently fused onto the Scroll Shaft.

Critical Assembly Points:

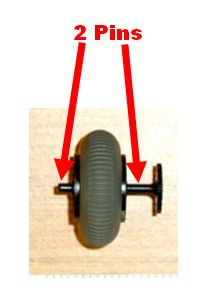

2 Shaft Pins: The Scroll wheel assembly is attached to the Scroll Base at 2 separate points that serve as bushings. It is critical that during assembly that neither one of the pins breaks off and that the shaft is able to rotate freely once assembled while at the same time stay in its location without coming loose.

Geometric Specifications:

Pin Diameter:

Upper Specification Limit (USL): 0.0975"

Lower Specification Limit (LSL): 0.0555"

Additional Quality Issues

IMPORTANT !!!The Scroll Base & The Scroll Shaft are made on the same injection molding machine simultaneously. The Scroll Shaft goes to the machine where the SCROLL WHEEL is made. The SCROLL SHAFT is placed in the machine and rubber SCROLL WHEEL is molded around it.

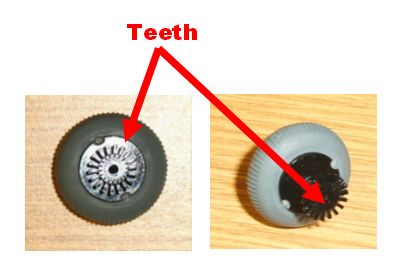

Shaft Teeth: The teeth on the Scroll Shaft are very fragile and can break off while handling, thus it is important that all teeth remain intact during the entire manufacturing process.

The following production issues are associated with non-conforming covers:

- Short shot,

- Missing teeth,

- Sink spots,

- Mold flashing,

- Warpage.

The following production issues are non-conformities on the cover:

- Bubbles,

- Burn spot,

- Surface imperfections,

- Black streaking,

- Part sticking in the mold.

Click Here To Go Back To The Inspection Station.

Click Here To Go Back To The Bill Of Materials.