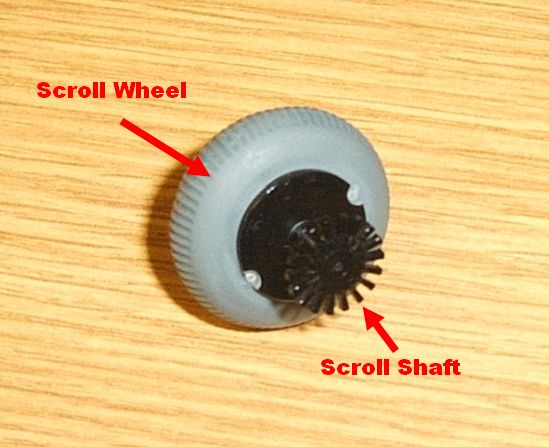

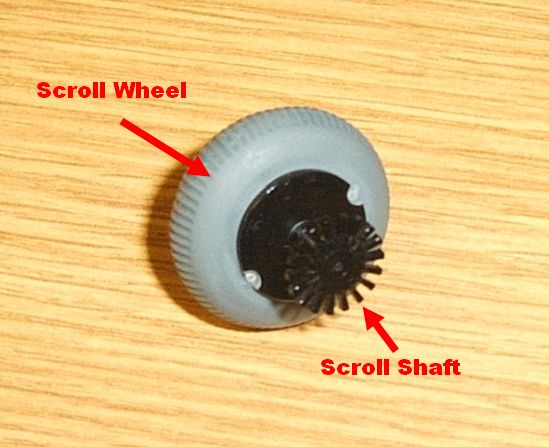

Scroll Wheel & Scroll Shaft (Scroll Wheel Assembly):

Part # |

Component |

Material Used |

Mfg. Process |

Qty. |

Production Rate |

Manufacturing Cost $ / Piece |

13 |

Wheel |

Grey Rubber |

Injection Molding to Shaft |

1 |

16 at a time |

$ 0.090 |

14 |

Shaft |

Black Plastic |

Injection Molding |

1 |

16 at a time |

$ 0.070 |

Total Cost: |

$ 0.160 |

The Scroll Wheel Assembly is made up from 2 other components; the Scroll Shaft and the Scroll Wheel. The Scroll Shaft is manufactured first then the Scroll Wheel is molded around the Scroll shaft in another process thus the Scroll Wheel is never a separate component as it is permanently fused onto the Scroll Shaft.

Scroll Shaft: This is the center part of the Scroll Wheel Assembly; it has a sprocket on one end that is used to intersect the path of a light sensor mounted on the PCB (Printed Circuit Board) to detect in which direction and the rate at which the scroll wheel is moving. Due to its design, this part is very fragile. It is made by an injection molding process from black PVC plastic at a rate of 16 parts at a time.

Scroll Wheel: This is part of the mouse that is touched by the user to engage the “Scroll” function of the mouse. It is made from gray rubber using an injection molding process in which the Scroll Shaft is inserted into the machine and then the Scroll Wheel is molded around it, when the process is complete, the Scroll Wheel and the Scroll Shaft become one piece. 16 parts are made at a time. This part is placed into the Base by the second operator in the subassembly workstation.

IMPORTANT !!! The Scroll Base & The Scroll Shaft are made on the same injection molding machine simultaneously. The Scroll Shaft goes to the machine where the SCROLL WHEEL is made. The SCROLL SHAFT is placed in the machine and rubber SCROLL WHEEL is molded around it.

Quality Issues

The shaft pin diameters are a critical quality characteristic and are measured and compared against specification limits.

Visual inspection is performed for each scroll wheel and shaft assembly. The following issues result in a part being classified as non-conforming: short shot, poor weld line, sink spots, mold flashing, and warpage. The following issues are classified as a non-conformity: bubbles, burn spot, surface imperfections, black streaking, and part sticking in the mold.

Click Here To Go Back To The Injection Molding Department.

Click Here To Go Back To The Bill Of Materials.